FOOD FOR CIRCUITS BOARDS

Richard Wool creates his circuit boards by turning soya-bean oils into an environmentally friendly bio-plastic. He mixes this with a glass-fibre substitute made by splitting the chicken feathers into small fibres. Feather fibres are made of keratin, the same protein that makes your hair and nails.

Richard chose chicken feathers because they are hollow, light and tough, providing the same properties as a traditional plastic circuit board. They also insulate electric currents so they don't interfere with the circuit running through them.

Meanwhile in the UK, materials scientist Roger Wise has developed a different solution to the circuit-board challenge. His team have designed a biodegradable board that can break down into natural materials, stopping boards being sent to the local landfill site or the fiery furnace.

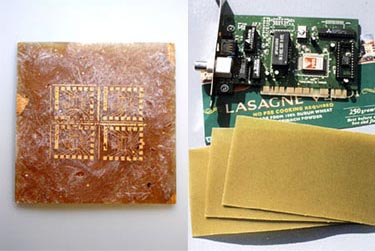

The design is deliciously simple - Roger's prototype is made of pasta.

Roger's prototype circuit is printed on a piece of lasagne. While it stays dry it is strong enough to have the metals and chips of a circuit welded onto it. Designers can also add a waterproof coating that makes the lasagne sheet last longer.

But remove the coating with chemicals, add soil and water, and the board breaks down, leaving the circuit's metals and chips unharmed, ready to be reclaimed and recycled.

via BBC news

Labels: material, process, sustainability, technology

0 Comments:

Post a Comment

<< Home